Waterjet Cutting for Stone & Tile

Waterjet machines using the KMT Waterjet pumps are perfect for creating corporate logos in decorative designs on walls or inlaid into floors, countertop parts, faucet and sinkholes as well as a smoother radius off sharp edges of slabs cut with saws.

KMT Waterjet is the only global waterjet manufacturer that partners with a variety of OEMs to offer many choices of waterjet tables from 2 Axis, 3 Axis, 5 Axis, dual cutting heads with a gantry waterjet table, as well as a combination waterjet and SawJet for cutting long slabs.

Ideal for Job Shop owners, stone cutting, marble cutting, granite cutting and Tile can all be fabricated by designers, for nontraditional “zero gap” cutting circular, square, oval, tile rugs, stone rugs, borders, murals, entry ways, kitchens, bathrooms, octagon patterns, medallion designs, border and accent tiles, polished, unpolished and textured porcelain.

Most of the interior designers specify the use of waterjet tables because of the intricate patterns and inlays in the hotels on the strip in Las Vegas, Nevada.

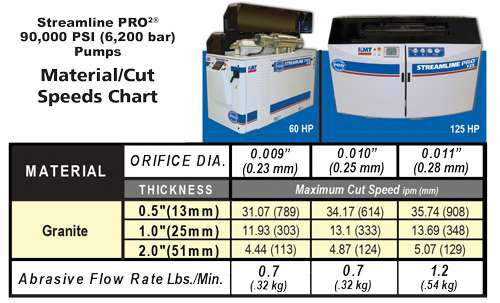

WATERJET CUTTING SPEEDS

|

For maximum performance cutting of hard materials.

|

|

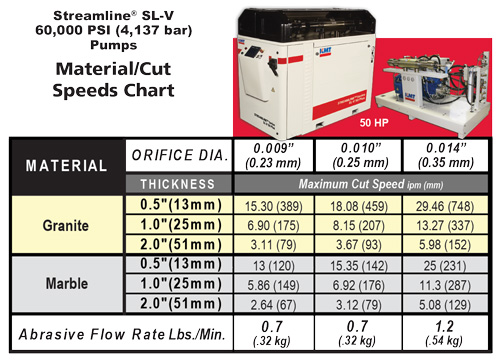

For cutting of soft and hard materials.

|

|

Ideally suited for lower demand applications.

|

ADVANTAGES OF CUTTING STONE WITH WATERJET

• Eliminates most secondary finishing… no rough edges

• Little or no waste of raw material

• No toxic fumes or dust (in contrast to saws & blades)

• No blade or saw sharpening

• Ability to cut the most intricate stone, tile and marble designs

• Ideal for cutting up to 12” (30 cm) of materials depending on density of product

• Eliminates the risk of discoloring or deformation

• Flexibility of Saw and Waterjet combination systems

STONE CUTTING FAQ's

• How fast can the material be cut?

The cutting speed is determined by the following factors: pump pressure, efficiency of high pressure generation and cutting head configuration, material thickness and properties, desired cutting edge quality, orifice diameter, abrasive quantity and abrasive quality. See also cutting speed table (Tab #1).

• What is the maximum material thickness that can be cut with waterjets?

With a thickness of approx. 10" (25 cm) we recommend considering whether cutting with a cutting disc would be a more cost-effective alternative.